Designing for Infection Control in the Workplace

Companies all across America are discovering what health care settings have long understood: that infection control adds a layer of complexity to cleaning protocols. In the age of COVID-19, the U.S. Centers for Disease Control and Prevention (CDC) has essentially said that all public spaces must develop and implement a plan for cleaning and disinfecting. Here’s a primer on what this means—and the implications for design.

Click here for resources and social media graphics

you can download and share!

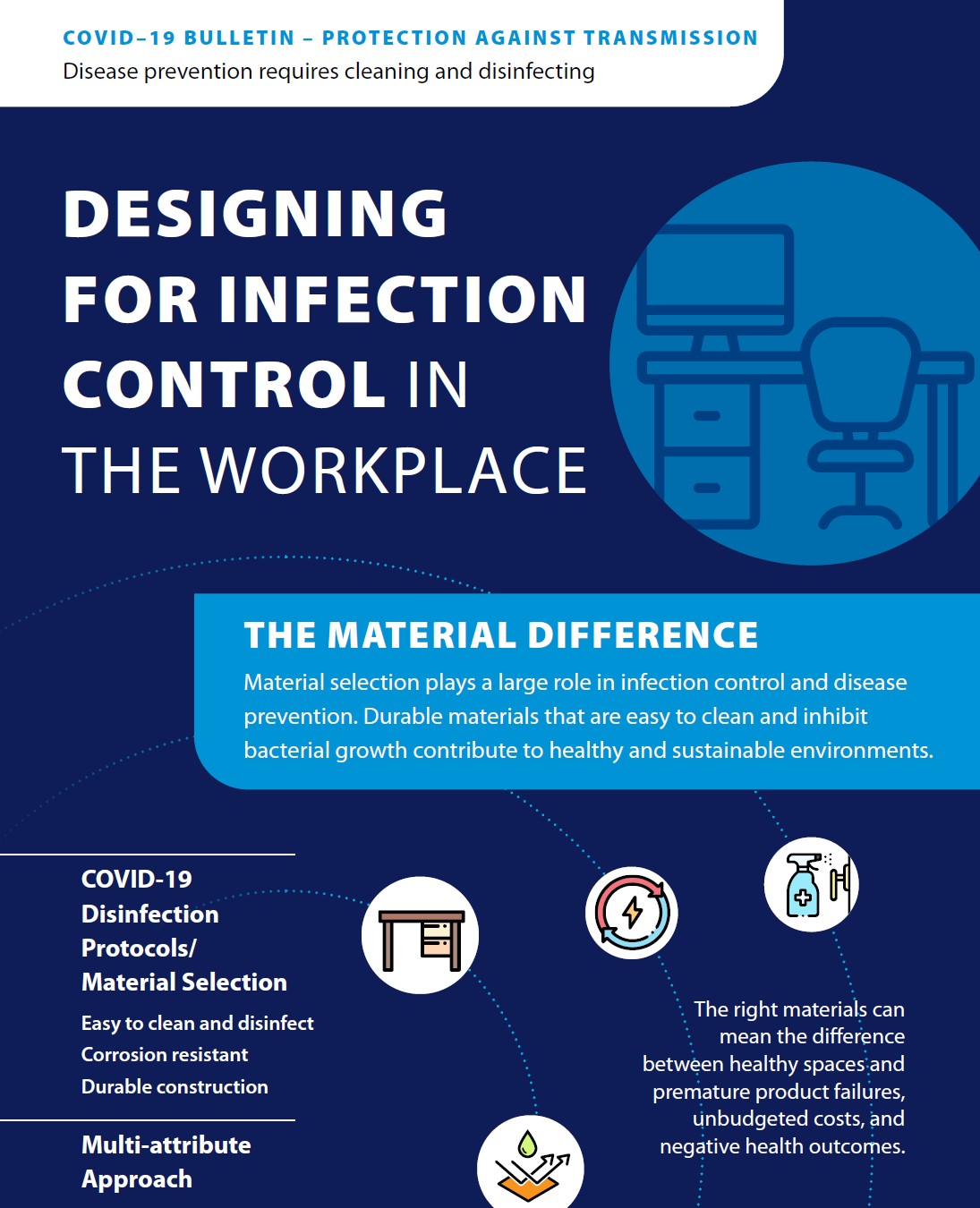

The Material Difference

Selecting the right materials can mean the difference between healthy spaces and premature product failures, unbudgeted costs, and negative health outcomes. That’s why applying a multi-attribute approach is critical—looking at performance characteristics, service life, environmental considerations, and health and safety. In other words: performance and sustainability go hand in hand.

With COVID-19 bringing new disinfection protocols to workplaces, it’s important to also consider how easy or hard a product is to clean and the impact of various disinfectants on that product. There are many high-touch areas at work that must be disinfected (e.g., telephone, drinking fountain, copier button); but they must also be disinfected without damaging the surfaces. Durable materials that are easy to clean and inhibit bacterial growth contribute to healthy and sustainable environments.

Collaborate with manufacturers and trade associations to understand the performance characteristics, the chemistry, and the manufacturer’s cleaning and disinfecting recommendations. Doing your homework upfront will save you unintended consequences down the road.

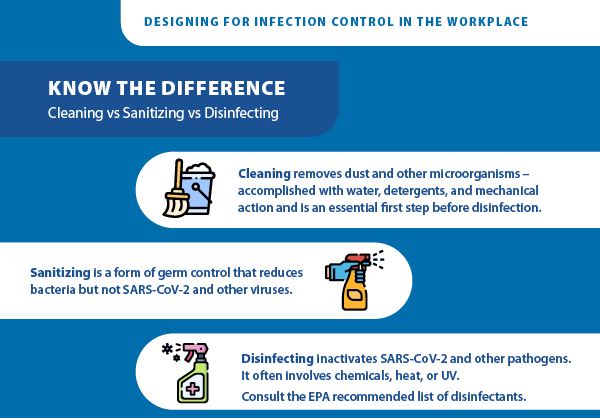

Know the Difference: Cleaning vs Sanitizing vs Disinfecting

- Cleaning removes dust and other microorganisms. It is accomplished with water, detergents, and mechanical action and is an essential first step before disinfection.

- Sanitizing is a form of germ control that reduces bacteria but not COVID-19 and other viruses.

- Disinfecting inactivates COVID-19 and other pathogens. It often involves chemicals, heat, or UV.

To determine what disinfectant is best to use for your purposes, consult the U.S. Environmental Protection Agency (EPA) recommended list of disinfectants.

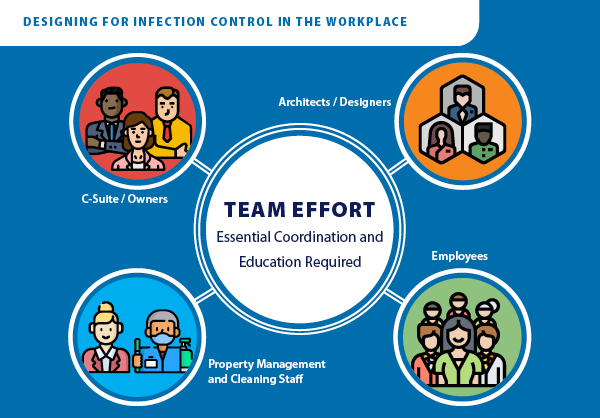

Success Depends on a Team Effort

These individuals are essential to coordinate with and educate in office environments.

- C-Suite / Owners

- Property Management (including cleaning staff)

- Architects / Designers

- Employees

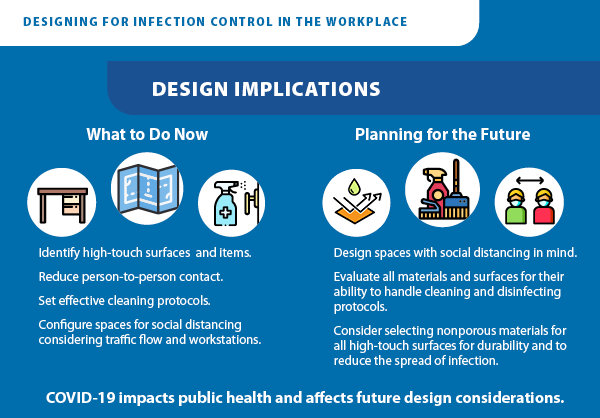

Design Implications: What to Do Now

From traffic flow to socially distanced workstations, designing for COVID-19 means:

- Identifying high-touch surfaces and items.

- Reducing person-to-person contact.

- Setting effective cleaning protocols.

- Configuring spaces for social distancing considering traffic flow and workstations.

Design Implications: Planning for the Future

While our understanding of the novel Coronavirus and its impacts on public health and public spaces is evolving, there are steps that companies can take today to apply a COVID-19 lens to future design. The impacts on public health affect future design considerations in the time of COVID-19 and beyond.

- Design spaces with social distancing in mind.

- Evaluate all materials and surfaces for their ability to handle cleaning and disinfecting protocols.

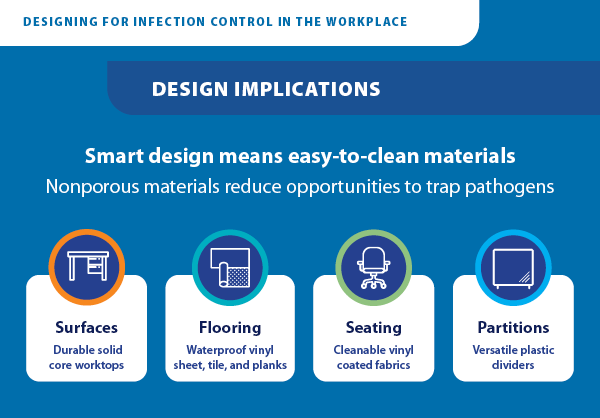

- Consider selecting nonporous materials for all high-touch surfaces for durability and to reduce the spread of infection.

Three Examples of Smart Design

- Flooring: Remove hard-to-clean carpet and replace with resilient products like waterproof vinyl sheet, tile, and planks.

- Upholstery: Select solid surface countertops and desktops. For seating, opt for simple designs made from hard, nonporous materials to reduce opportunities to trap pathogens. Where movable seating is used, consider cleanable vinyl durable coated fabrics.

- Partitions: Select plastic, acrylic, plexiglass, or vinyl partitions to install between workstations.

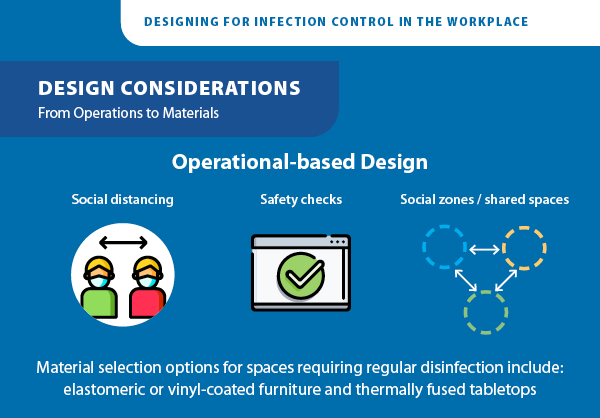

Design Considerations: From Operations to Materials

The way an industry operates will also influence how we design and maintain the spaces we occupy, and in turn, the materials we choose. There are three core operational considerations that offices need to put in place—and that need to be factored into design:

- Social distancing to ensure employees can maintain six feet of space as they work and move around the office.

- Safety procedures including temperature evaluation, access to masks and additional necessary PPE, and enhanced cleaning and disinfection protocol.

- Social zones / shared spaces and how to ensure occupant safety in shared community spaces such as eating areas, break areas, etc.

Each of these brings with it design implications as well as decisions about materials selection. For example, elastomeric or vinyl-coated furniture and thermally fused tabletops are a good option for break areas where employees are in shared spaces that need to be disinfected regularly and easily.

Review a more detailed flowchart describing design implications based on operational implications by clicking here.

Material Standards to Consider

There are many various guidelines and standards to consider. We’ve compiled a quick reference guide of some that you may want to review first. Click here to download.