Sika Sarnafil

A ZERO WASTE ROOF: A BEHIND-THE-SCENES LOOK

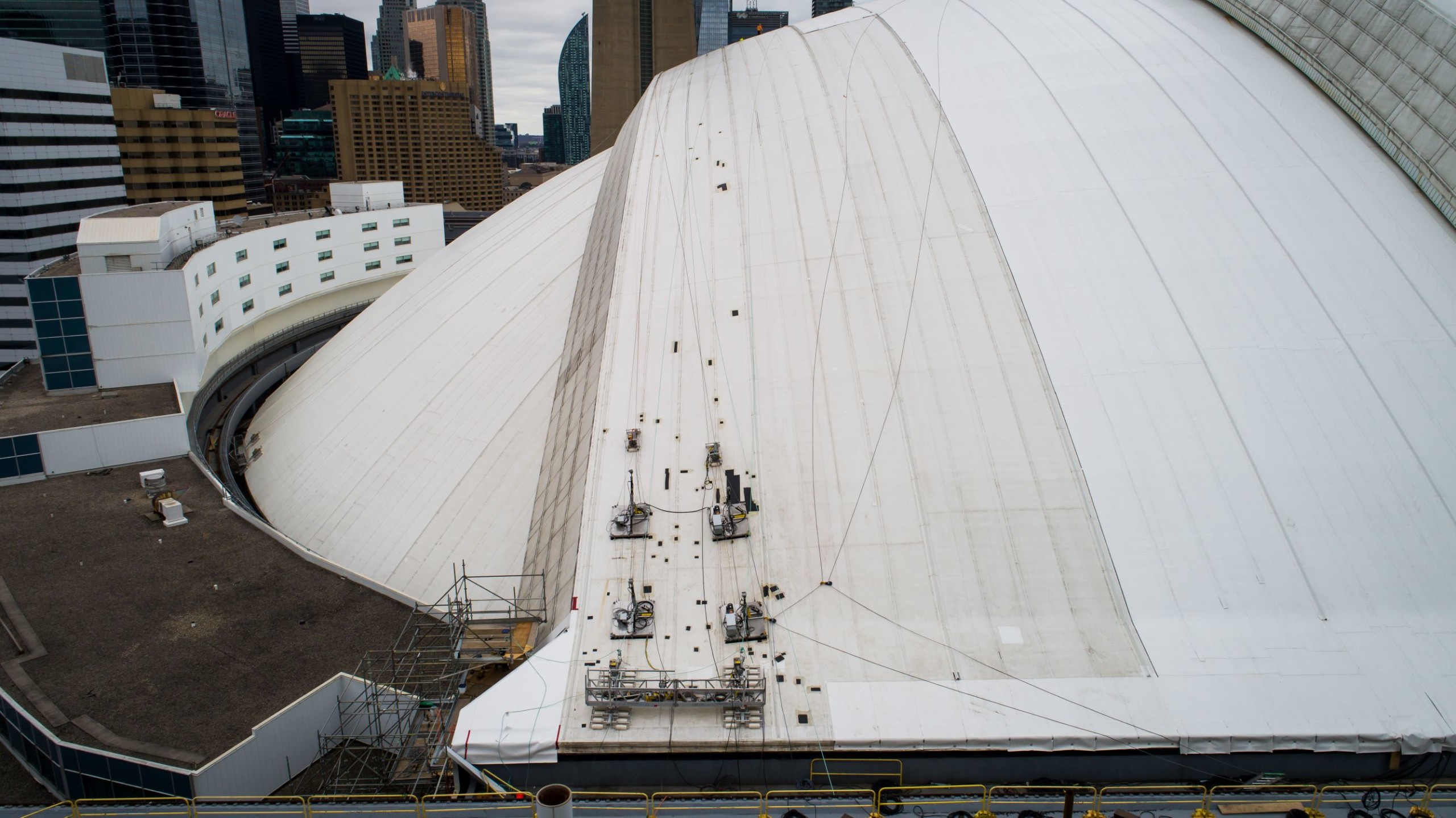

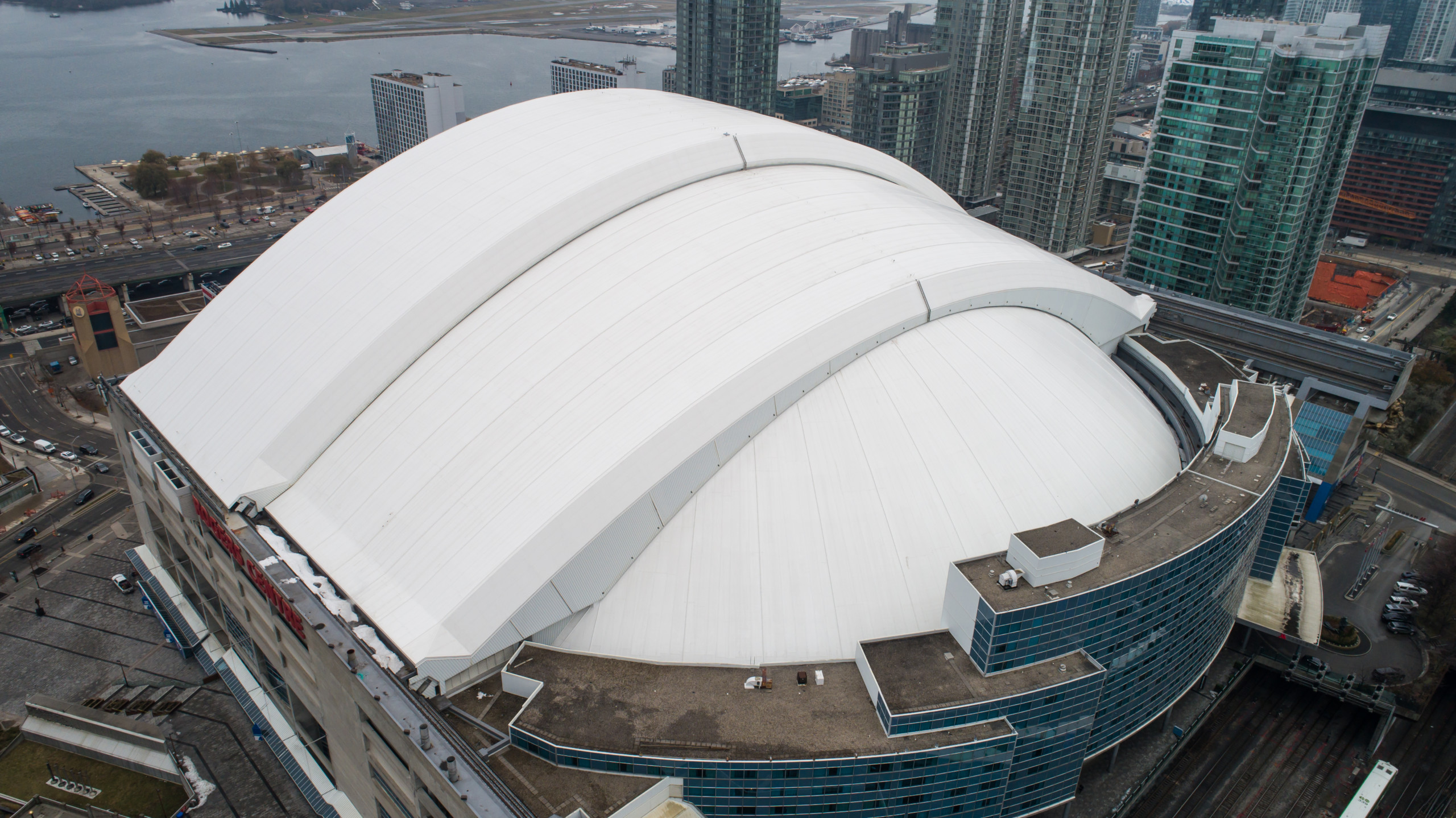

In cities like Toronto, Canada, where harsh winters can be unpredictable at best, a baseball stadium stands for so much more than just the game at play. For the iconic Rogers Centre, home to the Toronto Blue Jays, its 30-year-old vinyl roof was still performing admirably, protecting the fans underneath despite its advancing age. That came to an end in 2018 when a giant chunk of falling ice from the neighboring 1,800-ft tall CN Tower punctured the roofing system and its steel deck and caused significant structural damage to the stadium. With a limited construction window that had to fit in between baseball seasons, the owners took on an ambitious mission: to replace the existing roof during some of the toughest weather of the year.

It was time to look for a solution that would be durable for the next 30 years and sustainable in all respects.

For one, the roof must be durable enough to survive harsh winter conditions and withstand the avalanches of snow and resulting pressure of up to 20 feet of snow accumulation. The new roof also needed to help meet the Centre’s commitment to sustainability.

A ZERO-WASTE ROOF

The ask from the owners was to build a new roof with three core sustainability principles in mind—sending as little waste as possible to landfill, incorporating the use of recycled materials and a focus on system resilience. Having protected the stadium for the previous 30 years, and being fully recyclable, the same material was the clear choice for the new roof. For Sika Sarnafil, the manufacturer of the original roof, this was déjà vu with an opportunity to install a new roof 30 years later. Sika Sarnafil’s roofing “take back” program also enabled the original roof to be reclaimed and turned into a new roof for the Centre, which will protect and preserve it for decades more.

In 1989, when the original roof was constructed as the first fully retractable motorized roof arena to allow games to continue irrespective of the weather, Sika Sarnafil’s membrane was chosen to protect the roof. This membrane was made of 48 mil vinyl and fully recyclable. Now 30 years later, when it came time to replace the roof membrane, the initial investment and design decisions paid off: Sika Sarnafil was not only able to avoid sending all that material to landfill, but it was also able to convert it into useful raw material to construct new roofing membrane.

LONG-TERM DECISION MAKING ENDURES

Sustainability investments often carry long payback periods, but for Sika Sarnafil, these have been critical to their growth strategy. With the growing urgency around climate change and the pressure on companies to develop products that reduce their impact on the environment, Sika’s ability to eliminate waste sent to landfill has become a key element of the company’s sustainability mission.

As the first ANSI-NSF-347 certified platinum-rated roof membrane, the team at Sika Sarnafil knows a thing or two about producing highly sustainable roofing materials. In the end, the recycling of the original roof membrane managed to divert 460,000 square feet of materials from the landfill.

Since inception in the early 1990s, Sarnafil’s Roof Recycling Program has processed over 80 million pounds of recycled, pre- and post-consumer material while also converting 100% of its production line trimmings back into new roofing and waterproofing membranes. Once collected, used membrane is packaged, consolidated and shipped to a recycling facility where it is processed into a form that can be reintroduced into the new product manufacturing stream. With vinyl’s ability to be fully recyclable, and Sika Sarnafil’s roof “take back” program, their membranes offer a unique solution that helps reduce greenhouse gas emissions and provide a clean solution for industry.

“It is satisfying to see a 30-year-old Sarnafil roof come back full circle and get a new life as a roof membrane that will protect another building for years to come. Sustainability can begin right with product design by looking decades ahead and ensuring we’re manufacturing products that keep us and our planet safe. ”

– Bill Bellico, Vice President of Marketing

ABOUT SIKA SARNAFIL

Sika Sarnafil, the roofing division of Sika Corporation, is the first U.S.-based company to introduce a recycling program for commercial PVC roofing membranes and is the only company that recycles all of the collected material back into new membrane products. To date, 80 million pounds of processed recycled material have been diverted from the landfill through pre- and post-consumer recycling. And more than 2.3 billion square feet of new roofing membrane contains recycled PVC throughout over 25,000 projects. To learn more about Sika Sarnafil’s PVC roofing systems, click here.

Why +Vantage Vinyl™?

Sika recognizes that every company is at a different stage in their sustainability efforts, but the verification process provides every company with the opportunity to assess where they are at within their sustainability initiatives, highlight their accomplishments, and develop a path for continuous improvement.

Learn more about this company’s +Vantage Vinyl verification at ![]()

INTERESTED IN BECOMING +VANTAGE VINYL VERIFIED?

Take the first step toward earning + Vantage Vinyl verification by learning more here.