Occidental

How Carbon Removal as a Service is Poised to Aid the Clean Energy Transition

Imagine a world where all the carbon dioxide (CO2) that is emitted through activities such as manufacturing, air travel and hydrocarbon production could be captured with the carbon put right back underground where it came from. Imagine if a trip to your favorite destination came without the impact of global warming. Or a dinner of steak without the side dish of climate guilt.

This is the future that energy company Occidental and its subsidiary Oxy Low Carbon Ventures (OLCV) are demonstrating is feasible. Occidental is on a path to achieve net-zero emissions in its own operations and those associated with their products before 2050. And they are helping others reduce theirs too. Launched in 2018 to support Occidental’s carbon management efforts, OLCV has rapidly grown from investing in low-carbon technologies to working towards deploying several at commercial scale.

Dr. Robert Zeller, OLCV’s Vice President of Technology explains, “Oxy has a 40-year history of using and storing CO2 in conjunction with their oil and gas operations, but we have been using naturally-sourced CO2. Transitioning to human-made CO2 is not only the right thing to do but, with the right policy, it also makes good business sense.”

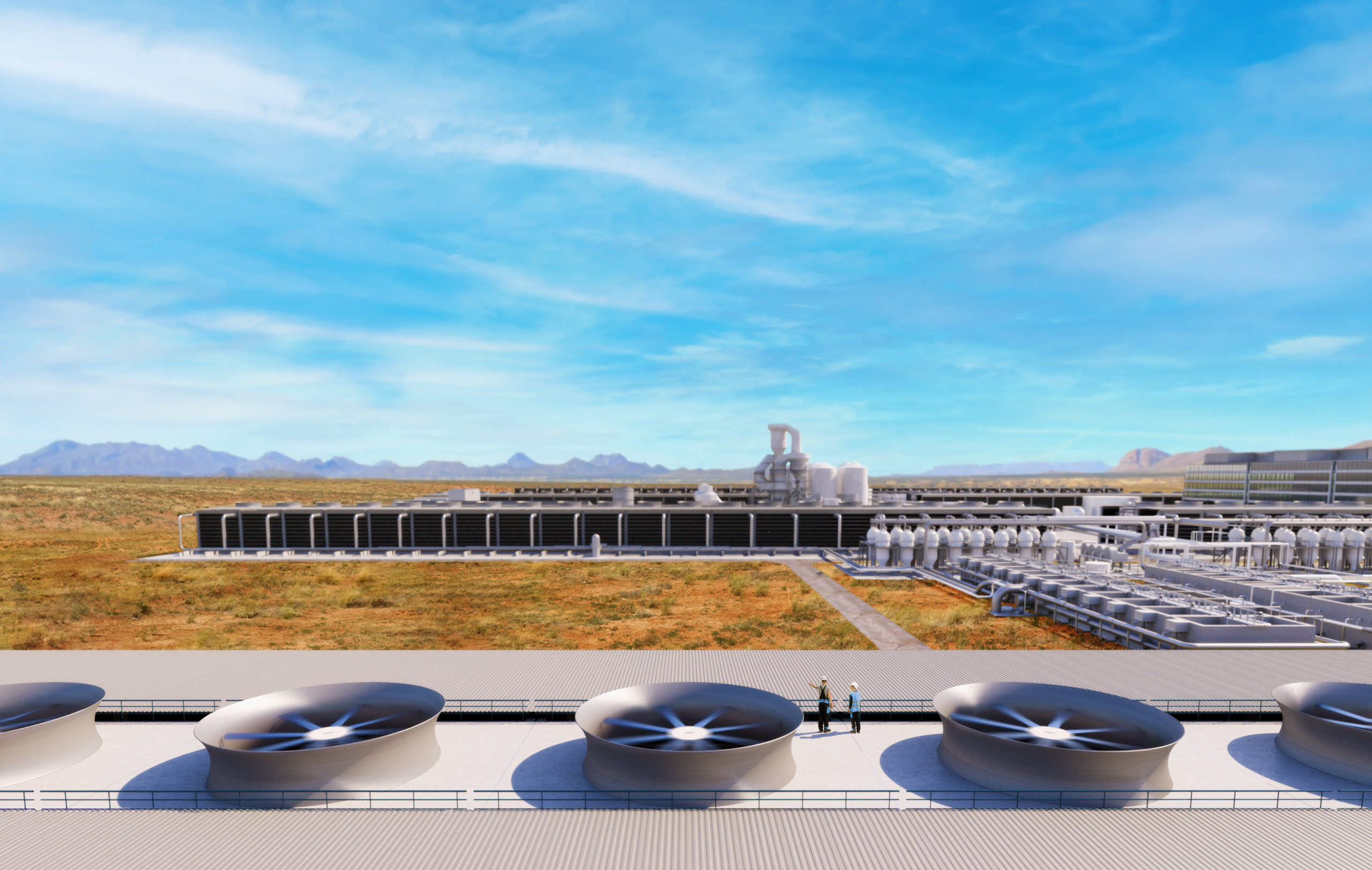

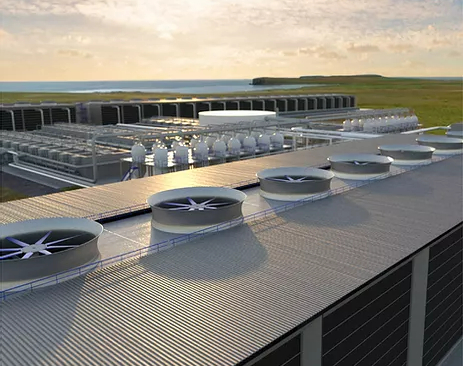

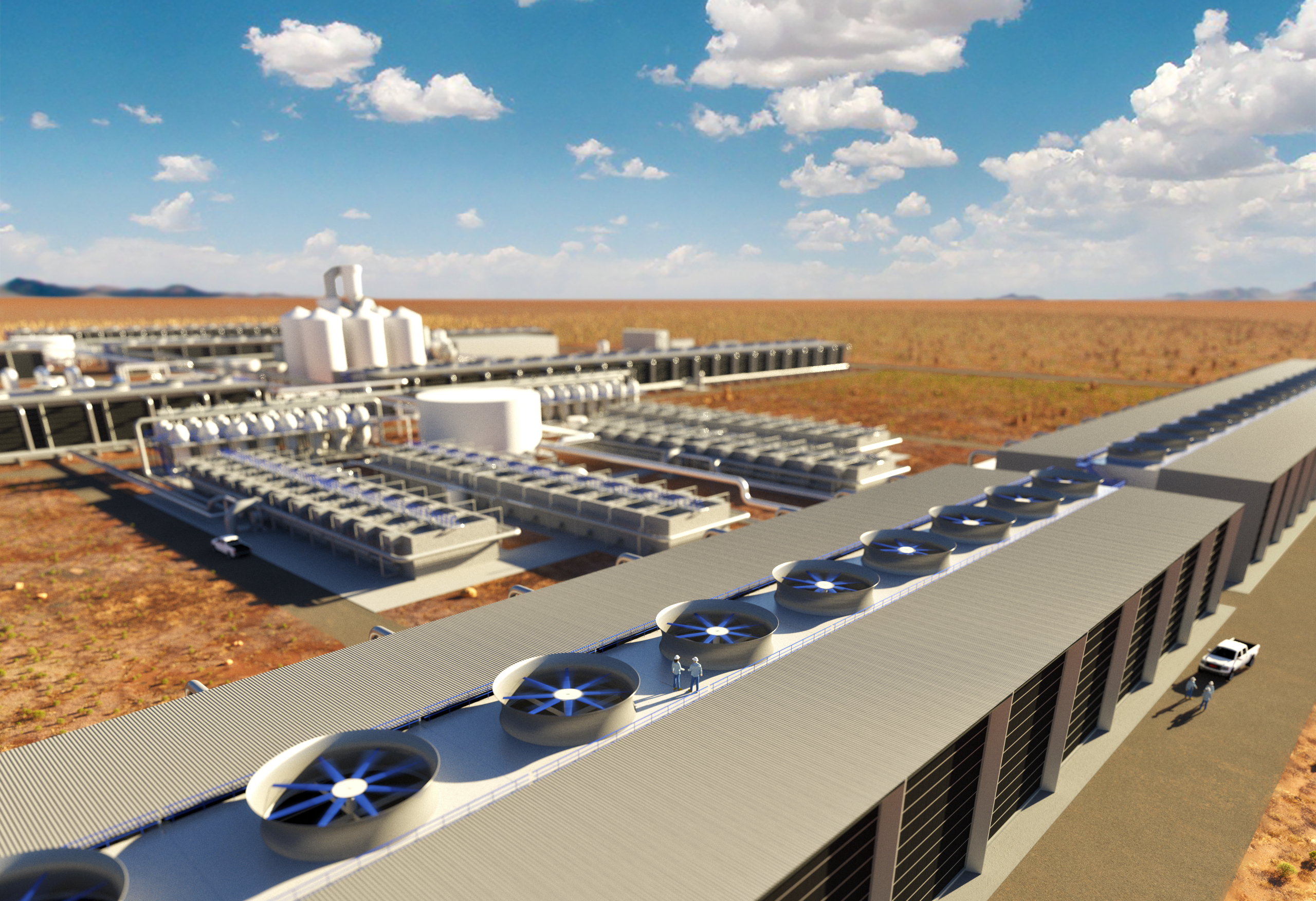

One of the company’s solutions is Direct Air Capture (DAC), a technology that captures CO2 directly from the atmosphere to be permanently sequestered deep underground. In 2020, Occidental formed 1PointFive, focused on large-scale commercial development of Carbon Engineering’s DAC technology. 1PointFive is planning to build the first DAC plant in the Permian Basin located in West Texas and Southeast New Mexico. By removing CO2 from the atmosphere, OLCV will be creating “negative emissions” and these negative emissions can be paired with oil production to produce net-zero or even net-negative oil. This net-zero oil is needed by hard-to-decarbonize industries, such as aviation and maritime shipping. OLCV is also evaluating the economic feasibility of permanently storing atmospheric CO2 in non-oil and gas geologic formations throughout the United States and the world as a carbon dioxide removal.

Here’s how DAC works: the technology captures and concentrates the CO2 in the atmosphere from 0.04% to over 95%. It uses a potassium hydroxide solution to capture the CO2 is compressed and liquified, and Occidental has the ability to securely inject it deep underground into suitable and certified geologic formations, where it becomes trapped and eventually turns into rock.

“Our subsidiary, OxyChem, is one of the world’s largest producers of potassium hydroxide and PVC, and both are key materials needed for the DAC technology” said Dr. Zeller. “Combining the innovative technology of Carbon Engineering with the deep know-how and experience of Oxy and OxyChem is leading to an acceleration in the development and commercialization of this critically needed technology.”

“We need to bridge today to tomorrow, balancing being bold on reducing carbon emissions, while also reducing other pollutants and growing high paying jobs.”

– Dr. Robert Zeller, Vice President for Technology, Oxy Low Carbon Ventures

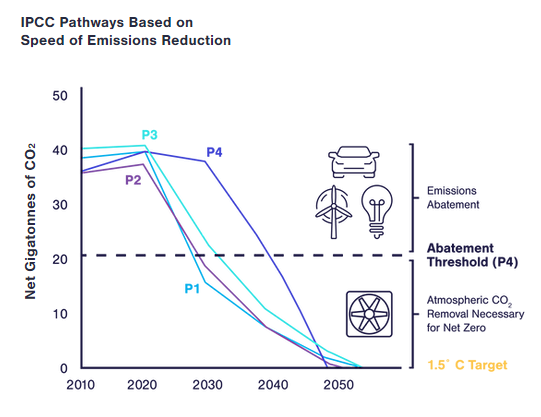

Measuring the opportunity

The opportunity of DAC to address rising greenhouse gas (GHG) emissions is vast. The United Nation’s Intergovernmental Panel on Climate Change (IPCC) and most recently the International Energy Agency (IEA) have reinforced the importance of carbon capture utilization and storage (CCUS) and DAC solutions in the global ‘race to zero’. These technologies will be critical, both in terms of decarbonization efforts and in removing billions of tons of CO2 per year that climate science requires to be slashed in just a few decades to keep global warming within 1.5°C.

In their quest to commercialize carbon capture technology and utilize the captured CO2, OLCV is actively engaged in many different types of projects in the CCUS space. A recent example: In April, OLCV announced that it had teamed with bioengineering startup Cemvita Factory to construct and operate a one metric ton per month bio-ethylene pilot plant using a jointly developed technology that uses human-made carbon dioxide (CO2) instead of hydrocarbon-sourced feedstocks.

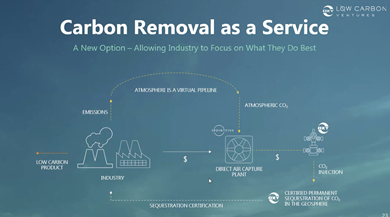

Emissions reductions one-for-one

“We need the most practical, economic solutions to meet our net-zero goals. Some facilities will implement point-source capture, some will change technologies, some will use emission reduction credits, such as from reforestation, to get to net-zero. Direct Air Capture provides a technology solution that can work in tandem with other efforts to enable even greater emissions reduction quickly, to achieve our net-zero goals,” says Dr. Zeller.

Carbon Removal as a Service could prove critical as part of the mix to help build a cleaner, safer future without costing thousands of jobs or disrupting local economies. Climate scientists have been warning industries, governments, and other agencies about the impact of CO2 on climate. Now with the target by the IPCC approaching – 2050 – a clean energy transition will require a whole host of solutions to make that kind of consequential transition happen globally.

Deployment of DAC technology and carbon capture projects have been slow due to uncertainties over the implementation of the 45Q tax credits. This slow adoption is similar to that of solar and wind deployment. The 45Q tax credit, expanded in 2018, is designed to accelerate deployment of CCUS and DAC. The credit is accessible to companies for each metric ton of qualified CO2 captured and either disposed of in secure geological storage or used for certain purposes. According to Dr. Zeller, the most impactful policy needed to accelerate deployment of CCUS and DAC projects is the direct pay for 45Q. Direct pay for 45Q allows carbon capture project developers to treat the full value for credits as an estimated payment on their tax return rather than applying the credit to their tax liability. It is expected that direct pay for 45Q will greatly simplify project financing thereby accelerating carbon capture projects nationwide.

Transitioning to a Sustainable World

“We need to bridge today to tomorrow, balancing being bold on reducing carbon emissions, while also reducing other pollutants and growing high paying jobs.” reminds Dr. Zeller. Because the calculation for many heavy emitting plants comes down to this: a) eliminate GHG emissions by closing down entire plants and risk laying off thousands of people or b) continue operating and improving the plants but balance its emissions through technologies such as DAC for a more managed transition to a lower carbon future.

As the world’s largest handler of CO2, Occidental knows a thing or two about carbon management. The task ahead is twofold: improved government incentives and support of DAC technology, and changing mindsets that allow adopting solutions that come with short- and long-term payoffs. And recognition that climate action can mean endless opportunity – for jobs, for technology, and for how we make this planet habitable for all of us and for future generations.

About Occidental Chemical Corporation

Occidental Chemical Corporation, headquartered in Dallas, Texas, is a leading manufacturer of polyvinyl chloride (PVC) resins, chlorine and caustic soda. Within OxyChem is OxyVinyls, which also manufactures vinyl chloride monomer (VCM), and its precursor, ethylene dichloride (EDC). It is the largest VCM producer and the third-largest PVC supplier in the United States. Globally, Oxy is the second-largest merchant marketer in the world of chlorine and the largest marketer of its co-product caustic soda—both of which are necessary for the creation of PVC. OxyChem is a wholly-owned subsidiary of Occidental, as is Oxy Low Carbon Ventures.

Why +Vantage Vinyl™?

Earning the Vantage Vinyl verification further reflects our company’s leadership in sustainability and illustrates our ongoing commitment to be the Partner of Choice® for our suppliers, customers and the communities where we operate.

Learn more about this company’s +Vantage Vinyl verification at ![]()

INTERESTED IN BECOMING +VANTAGE VINYL VERIFIED?

Take the first step toward earning + Vantage Vinyl verification by learning more here.